Eleanor Pritchard is a textile designer and weaver

For the last five or six years I have bought a new paper shredder on an almost annual basis. No matter how carefully I feed them, one sheet at a time, each one in turn has come to a grinding halt. Despite my best coaxing and cajoling, reversing their gears, cleaning their teeth and fanning their motors, none have stayed the course.

The last one I bought came with five star reviews and heavyweight claims, but in the end it fared no better than its predecessors. So this time, rather than buy another electric shredder, I looked for something much simpler.

I now have a small hand-operated shredder which sits on the window sill between the succulents and the old school Rolodex. It is quiet, discreet, low tech, and immensely satisfying to use. It operates on the same principles as the other shredders - you feed a sheet of paper through a slot and into a series of parallel toothed wheels - the only difference being that you turn a hand-crank to rotate the workings. Because you are operating the mechanism by hand you can feel when it is overloading and adjust it as you go, rather than waiting for the inevitable groaning complaint. I have had it for some months now and it shows no signs of shirking.

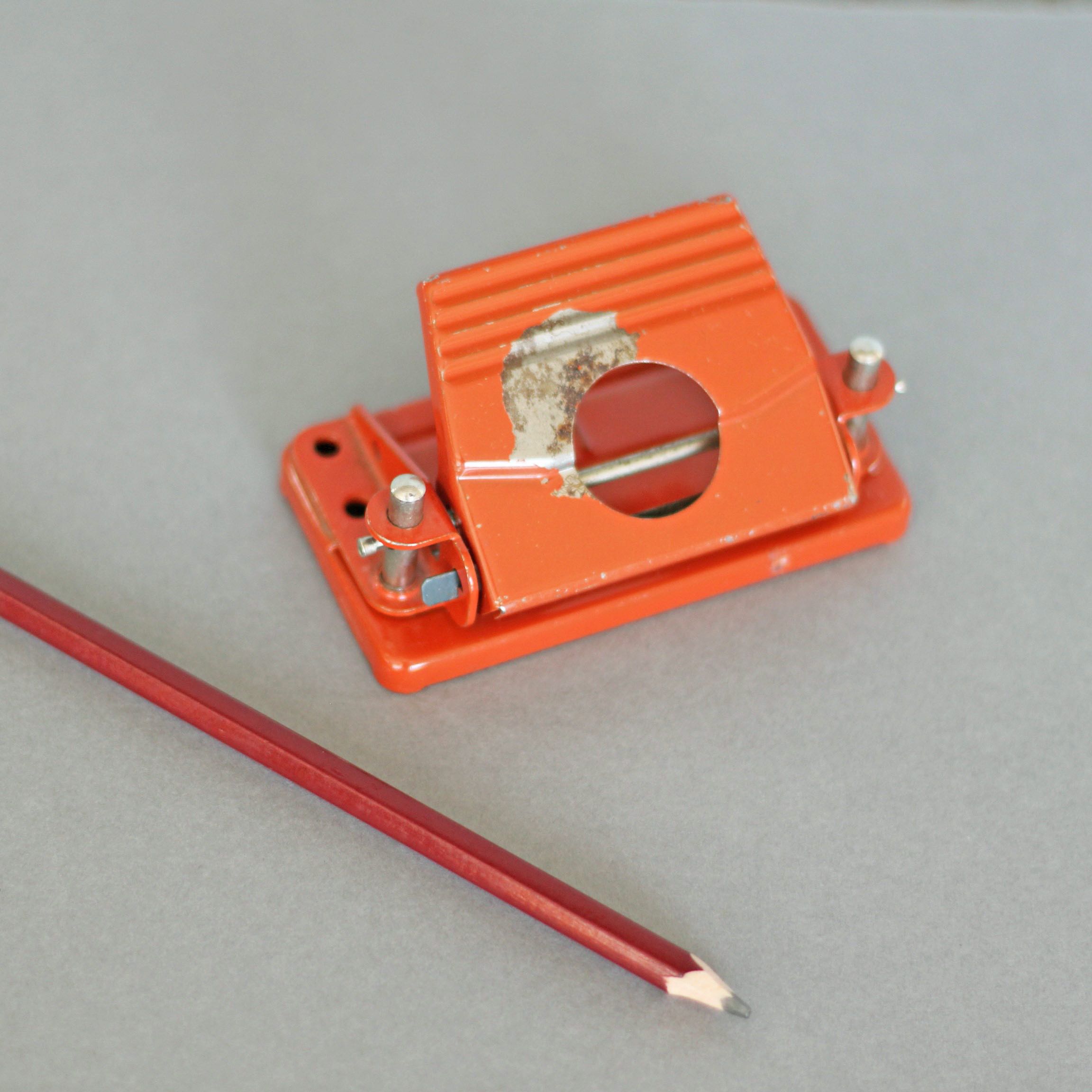

In a similar vein I have swapped from plastic mechanical pencils in the studio to wooden ones. In many ways my Pentels were perfect - always sharp and at-the-ready, equipped with their little black eraser ends, and such a pleasing egg-yolk yellow. But it seems irresponsible and wasteful to go on ordering plastic pencils when I have drawers of unused wooden ones.

And I find that I love the ritual of sharpening them. Personally I favour a number 6 Opinel knife, which brings with it all the nostalgia of pocket money souvenirs from 1980’s holidays in France. I love the smell of the newly cut wood; the fragments of coloured paint on the pairings; and the sound of the blade whittling the lead. As with the paper shredder, because you are operating it by hand you can shape the lead to your liking - long and tapered or short and angled.

All this has got me pondering about appropriate levels of technology. I am no Luddite and would not be without an up-to-date computer, iPad or digital camera. It is simply a question of what is appropriate to the task in hand.

Happily I gave a great deal more fore-thought to the choice of my studio sewing machine and sampling loom. The former is a 1960’s ex-ILEA Bernina. It can only do straight stitch and zig zag and it is perfect for the studio - I have no need for fancy stitching. It is a real work-horse - Swiss engineering at its best.

My studio sampling loom is a George Wood peg-and-lag 24 shaft wide width loom. It came to me after one careful owner and now has a considerable mileage on the clock. The dobby head is a simple mechanical computer - you literally ‘programme’ it with a series of wooden pegs that carry the binary code for the lifting pattern. It is simple, mechanical and analogue.

I have no doubt that many weavers would favour newer ‘computerized’ looms with their vast memory banks of patterns; interfacing with increasingly sophisticated weave design software. But for me the George Wood is perfect. Because you programme mechanically and slowly; by hand; you plan ahead and think much more carefully about what you are doing. For me, the pace and the parameters are vital to the design process.

And the maintenance is incredibly straightforward - consisting simply of tightening a nut here, trying a knot there, and applying a little engine grease now and then.

Sometimes complex is good, but often simple is better.